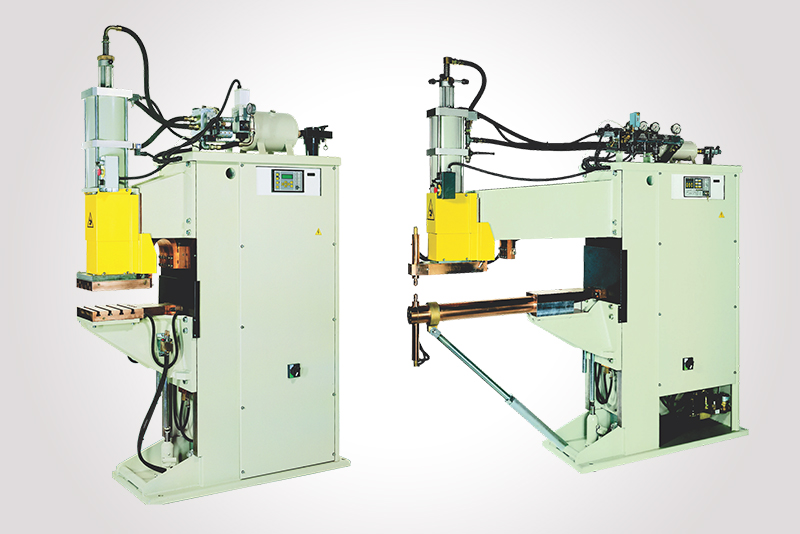

Space Saving: As machine is mounted on bench, the lower space can be utilized for storage of WIP and FG

Higher Electrical Efficiency : Due to small form factor and shorter secondary lengths, these machines are more energy efficient.

Welding currents upto 25 kA and electrode force upto 800kGF make it pissible to weld most of the jobs.

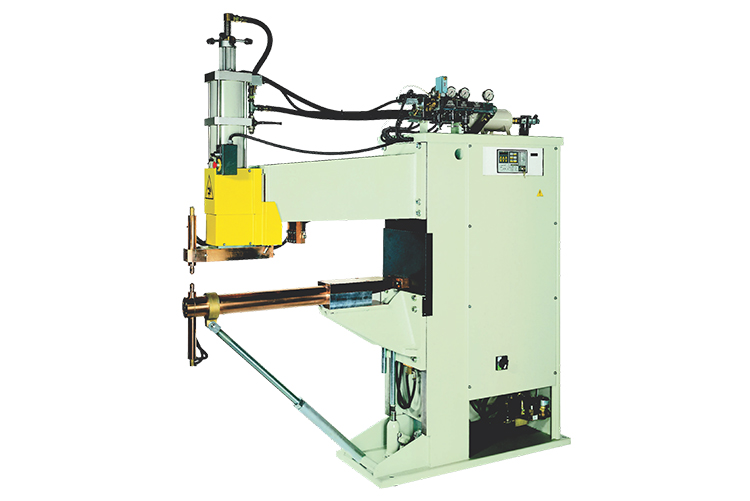

Space Saving: As machine is mounted on bench, the lower space can be utilized for storage of WIP and FG

Higher Electrical Efficiency : Due to small form factor and shorter secondary lengths, these machines are more energy efficient.

Welding currents upto 25 kA and electrode force upto 800kGF make it pissible to weld most of the jobs.

Welding of 60 to 70 Nuts per Minute is possible with one machine and one operator

No need for operator to put nut between electrodes and as such no possibility of accidental injury to the operator

Nut is placed with right orientation every time. Thus savings from probable damaged parts, damage to electrodes

Nuts do not fall down on shop floor, saving the material wastage

Takes only a few hours for installation and is productionized on same day

Facilitates welding of different nuts by switching of nut feeder and can operate only spot welder

Saves power by switching off the vibrator when the supply hoseis full

9.30 Am - 6:00 Pm

© 2025 Created By blMedias

09:00 Am - 11:00 Pm

© 2024 Created with Royal Elementor Addons