Continuous Innovation is in the genes of TECNA Weldcon. This, coupled by the two strong teams of TECNA, Italy and TECNA Weldcon, India, the two squad continues to forge ahead with newer ground-breaking solutions for customers in the field of Resistance Welding.

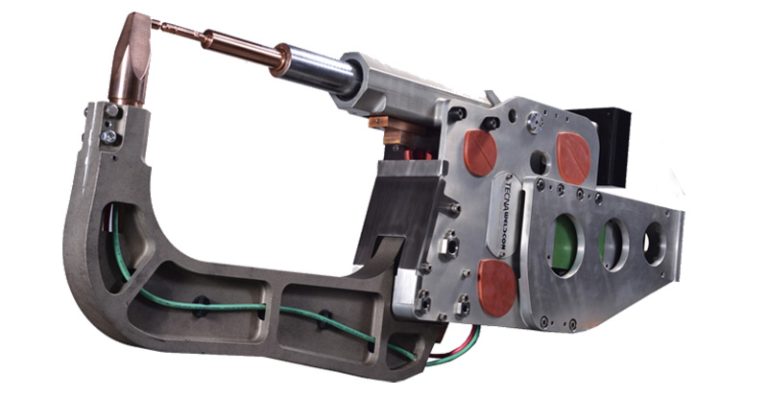

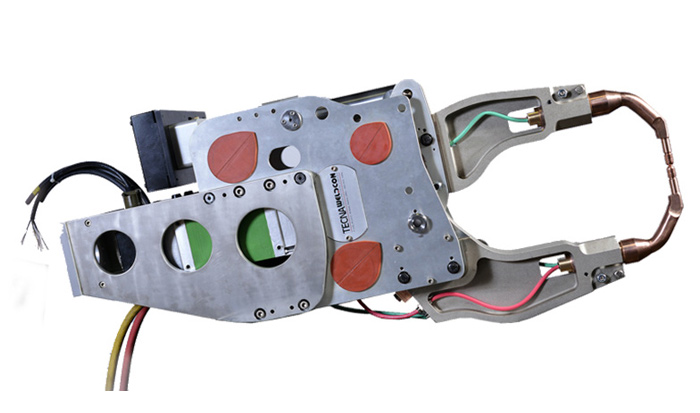

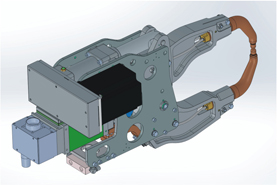

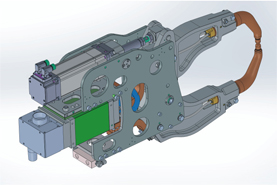

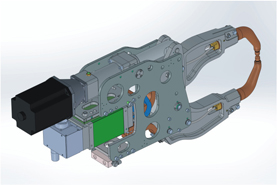

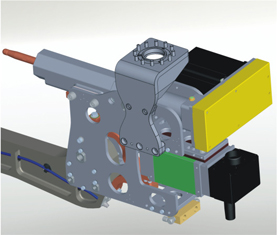

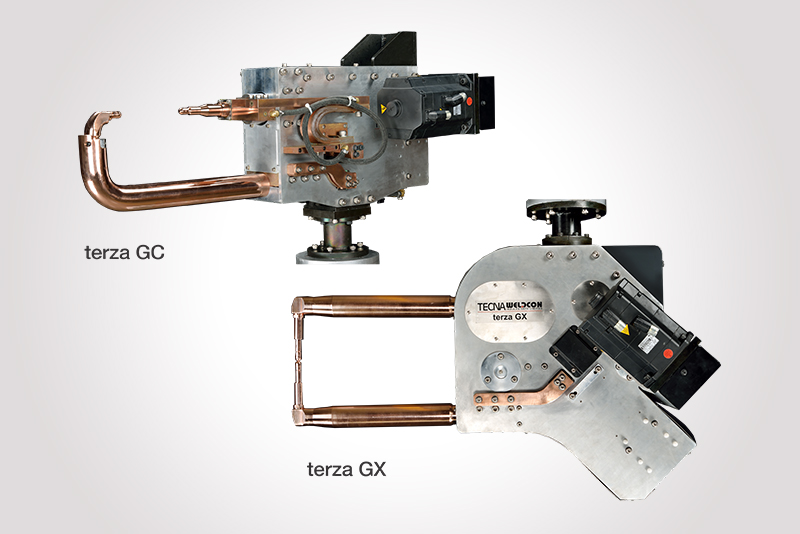

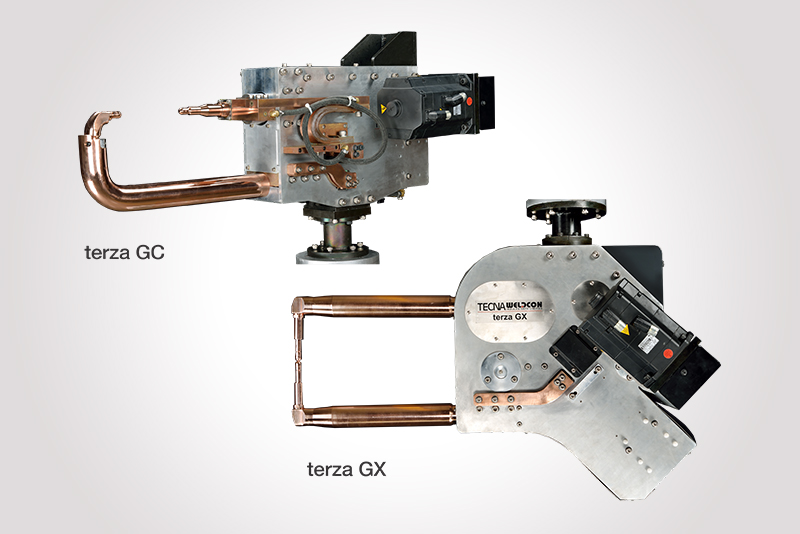

This is the fourth generation of Robotic Spot-Welding Guns from TECNA Weldcon in last 10 years. The design has undergone tremendous changes. The new design is based on the adoption of customer’s feedback and thorough understanding of actual customer needs on shop floor.

Emphasis is put upon the Reduction in Weight, in Number of Parts, Increased Efficiency and Ease of Maintenance. Over 60% of the parts are common in both, X and C type guns. Over 80% of parts subjected to wear & tear are common. This will greatly reduce the spares inventory and economize the operations.

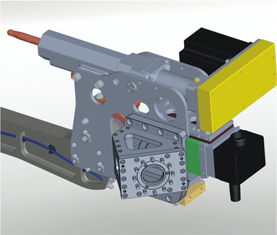

The SuperSlim gun is designed to accommodate any make of motor provided by the robot manufacturer when using Servo Mechanical Drive (Traditional belt-pulley combination).

The SuperSlim gun is also designed to adapt to leading actuator manufacturers like Tolomatic, Diakont and others as per customer's choice.

There is available an option of using Direct Drive Technology when using motor provided by robot manufacturer.

Advantage of the latter two drive option is improved dynamics of the gun during high-speed motion of the robot. This reduces “Apparent Weight” of the gun, as perceived by robot due to momentum, and helps robot to move at faster speeds.

Another significant advantage of using either Direct Drive Technology OR The third-party actuator is it senses the sheet thickness very accurately up to 0.10 mm before welding. This comes handy when customer wants to detect missing or wrong parts.

These are designed and tested for nonstop operation of 30 million cycles without need of any maintenance. Most interesting part is that these drive technologies are adaptable to same gun, making it possible for customer to change drive technology at any time in future.

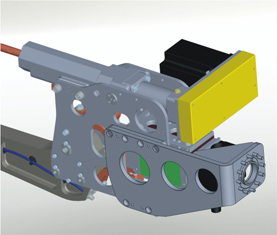

This has become ever so more important. With reduction in weight, robot will achieve higher air cutting speed. Customer can use robot of lesser payload, thus saving money at the time of investment and recurrently on utility costs. Compact size helps customer plan for high density layout saving precious shop floor space. When installed on old robots with higher payloads, the gun will enable customer to operate at faster speeds, reducing production time and lower utility cost consequently.

The SuperSlim Guns can accommodate new design of gun arms and make them suitable for new project. In these times of fast design changes in products and shortened products life cycles, it is important to make sure that our investments are flexible in nature. SuperSlim Guns make sure that customer can adapt the gun for new projects just by changing Gun Arms and in some cases just by changing the electrode holder!

The use of speciality Aluminium Alloy ensures that the mechanical strength of the structure is improved, even with the weight reduction, thus achieving superior strength to weight ratio. This means longer service years and more returns on investment. New symmetrical design ensures that the gun is easier to be handled by robots with improved dynamics.

Customer can change transformer capacity from 36kVA to 105kVA in AC and 56kVA to 105kVA in MFDC technology while using the same gun body. This provides additional advantage in investment protection.

Super Slim Robot Guns, due to its lower weight, when used with their matching robot payloads, reduces footprint of a welding station. This enables customer to accommodate more robots in the same space.

As we know, real estate comes at serious premium!

Build structure of SupeSlim gun is designed to operate at higher welding forces upto 1 Ton on electrode. By changing the transmission configuration and actuators, the same machine can easily be upgraded or adapted to provide high electrode force, when needed.

Various options for mounting on robot makes simulation exercise simple and quick. This also ensures better approach to spot, thus reducing cycle time.

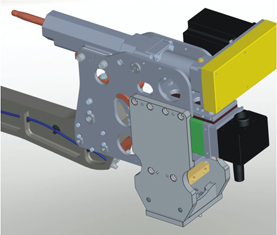

For SuperSlim Medium Frequency Guns, the Control Unit TE700/TE710 is industry trusted and proven control unit. Working in tandem with Inverter Units of various size and capacities, according to the capacity of welding transformer, the control unit offers seamless user experience for those who are already familiar with TECNA control units for AC machines.

TECNA Weldcon Medium Frequency Solution, is BY DEFAULT based on adaptive technology. Customer need not make any additional investment to enable adaptive mode of working!

For SuperSlim AC guns, they are supplied with trusted and proven controller TE550. AC control units have a possibility of setting times to a precision of half-cycle. It will also correct, welding current every half cycle of mains supply. Thus, achieving more precise control on welding current. For mission critical application, Constant Energy Add-on is available as on option. This option monitors energy dissipated in welding joint and keeps it constant by adjusting welding time and current, autonomously, within prescribed window limits

For SuperSlim Medium Frequency Guns, the Control Unit TE700/TE710 is industry trusted and proven control unit. Working in tandem with Inverter Units of various size and capacities, according to the capacity of welding transformer, the control unit offers seamless user experience for those who are already familiar with TECNA control units for AC machines.

TECNA Weldcon Medium Frequency Solution, is BY DEFAULT based on adaptive technology. Customer need not make any additional investment to enable adaptive mode of working!

For SuperSlim AC guns, they are supplied with trusted and proven controller TE550. AC control units have a possibility of setting times to a precision of half-cycle. It will also correct, welding current every half cycle of mains supply. Thus, achieving more precise control on welding current. For mission critical application, Constant Energy Add-on is available as on option. This option monitors energy dissipated in welding joint and keeps it constant by adjusting welding time and current, autonomously, within prescribed window limits

9.30 Am - 6:00 Pm

© 2025 Created By blMedias

09:00 Am - 11:00 Pm

© 2024 Created with Royal Elementor Addons